- Browse Categories

-

Energy Storage Series

- EV Chargers

- Ring Main Unit Series

- LBS and Recloser

- High & Low Voltage Complete Series

- Distribution Transformers

- Components

- Distribution Automation Terminal Series

- Digital Platform System

- EV Chargers

- Subscribe

-

Get email updates on new products

- Hot Product

- ExhibitionMore>>

-

-

EP 20 concluded, Comking depicted a new vision of the intelligent and sustainable development of the power world

2020 Shanghai International Electric Power Equipment and Technology Exhibition. It has been successfully concluded on December 5~ -

Dry air insulated switchgear debuted at the Asian Power and Electrical Exhibition

From June 6 to 8, 2016, Comking Electric was invited to participate in the 2016 Asian Power and Electrical and Smart Grid Exhibition.

-

- Contact Us

- Please contact our customer care team for customized services.

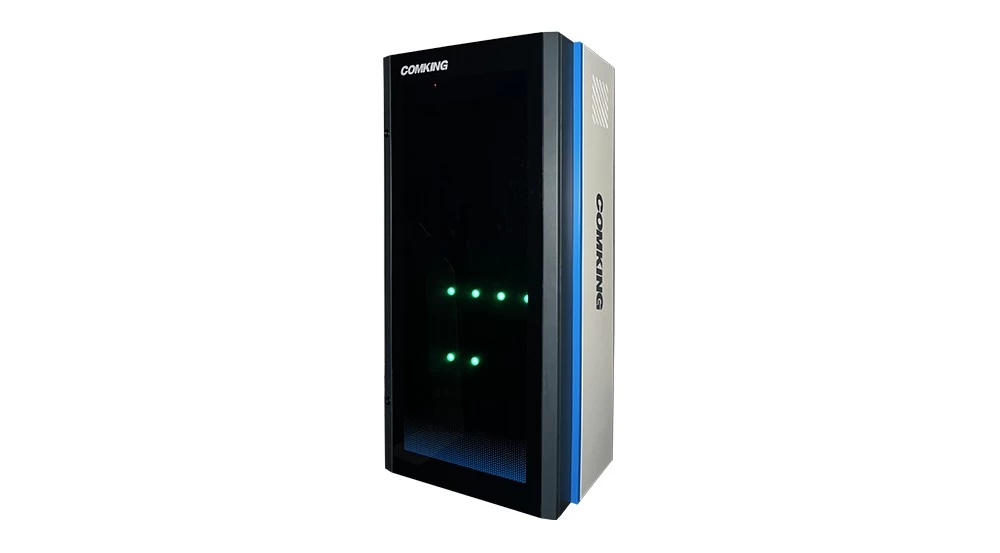

CKPM602 Distribution Automation Terminal

- Maximum support for 16 circuit loop intervals

- 3 channels of remote measurement: IA, IB, IC, or IA, IC, 3I0

- 6 channels of remote signals: open position, closed position, not stored energy, grounding switch, isolation, standby

- 2 channels of remote control: trip, close

- Voltage and current at 0.2 level, power at 0.5 level, frequency at ±0.01 level

►Product Overview

The CKPM602 Distribution Automation Terminal (hereinafter referred to as DTU) is suitable for distribution networks with voltage levels of 10kV and above. It can be applied to distribution automation systems with dual power supply, operating in either open loop or closed loop configurations.

The CKPM602 is a terminal for box-type distribution automation stations, providing local and remote monitoring, control, and fault detection functions for switchgear through the current, voltage, and status quantities of various lines within the station.

The CKPM602 Distribution Automation Terminal can function as a traditional distribution automation terminal or as a product for integrated primary and secondary distribution automation.

►Product Features

Powerful Hardware and Software Platform

The device utilizes advanced digital signal processing technology, high-speed industrial network communication technology, multi-CPU integration technology, embedded industrial chipsets, and a multitasking real-time operating system, ensuring strong stability, high reliability, excellent real-time performance, broad environmental adaptability, and powerful functionality, thereby meeting the power system's requirements for reliability and real-time performance. The device features a high-precision 16-bit A/D converter, with current and voltage measurement accuracy reaching class 0.2, and power measurement accuracy reaching class 0.5.

Specialized Structural Design

The device features a 19-inch 4U standard chassis with a popular modular front-pluggable structure, compact size, and shallow depth, making installation convenient. It supports a maximum of 16 circuits, with each circuit comprising 3 remote measurement channels, 6 remote signal channels, and 2 remote control channels. The functional modular design allows for the addition or removal of functions through plug-in modules, enabling plug-and-play capability and supporting hot-swapping.

Strong interference immunity, no adjustment required, and easy maintenance.

The device utilizes multi-level isolation and effective shielding measures, with careful consideration of various interference mitigation strategies in the design from the chassis to the printed circuit board and the selection of components. The group screen requires no external interference mitigation measures, thereby simplifying both design and operational maintenance.

The entire unit contains no adjustable components and employs high-precision, high-stability industrial-grade devices to prevent deviations caused by environmental changes or prolonged operation. A comprehensive self-check function logs detailed records of various anomalies within the device, which can be uploaded to the main station. An integrated temperature measurement system effectively monitors the internal environmental conditions of the device. Successfully passed national-level electromagnetic compatibility (EMC) tests for lightning surge, electromagnetic radiation, transient interference, and 12 other categories at the highest level.

Information security is reliable.

Equipped with a one-way authentication function that complies with National Regulation Document No. 168 [2011] utilizing asymmetric key technology. It features a comprehensive maintenance permission management system, requiring authorization verification before any maintenance operations can be performed on the device.

User-friendly maintenance tools.

The device maintenance tool software offers three primary configuration functions: device channel configuration, fixed parameter settings, and forwarding point table configuration. With these three configuration functions, various engineering applications can be completed through configuration without the need to modify the program, significantly enhancing the device's reliability. The tool boasts a high level of user-friendliness, conveniently assisting on-site commissioning with the viewing of remote signals and remote measurements, output of remote control, device logs accurate to the microsecond, GPRS module configuration, and testing of IEC101 and IEC104 protocols.

►Product Specifications

- Maximum support for 16 circuit loop intervals

- 3 channels of remote measurement: IA, IB, IC, or IA, IC, 3I0

- 6 channels of remote signals: open position, closed position, not stored energy, grounding switch, isolation, standby

- 2 channels of remote control: trip, close

- Voltage and current at 0.2 level, power at 0.5 level, frequency at ±0.01 level

- 3 channels of RS232, 3 channels of RS485, and 2 channels of RJ45

- 2 channels, with 0.2 level switch quantity and status quantity input voltage: DC24V/DC48V, starting voltage (60%~75%)

- ≤2ms, debounce 1~65535ms configurable

- on, off ≥ 10 5, pulse width 1~65535ms configurable

Click Distribution automation terminal Intelligent diagnosis to learn more about the products.