- Browse Categories

-

Energy Storage Series

- EV Chargers

- Ring Main Unit Series

- LBS and Recloser

- High & Low Voltage Complete Series

- Distribution Transformers

- Components

- Distribution Automation Terminal Series

- Digital Platform System

- EV Chargers

- Subscribe

-

Get email updates on new products

- Hot Product

- ExhibitionMore>>

-

-

EP 20 concluded, Comking depicted a new vision of the intelligent and sustainable development of the power world

2020 Shanghai International Electric Power Equipment and Technology Exhibition. It has been successfully concluded on December 5~ -

Dry air insulated switchgear debuted at the Asian Power and Electrical Exhibition

From June 6 to 8, 2016, Comking Electric was invited to participate in the 2016 Asian Power and Electrical and Smart Grid Exhibition.

-

- Contact Us

- Please contact our customer care team for customized services.

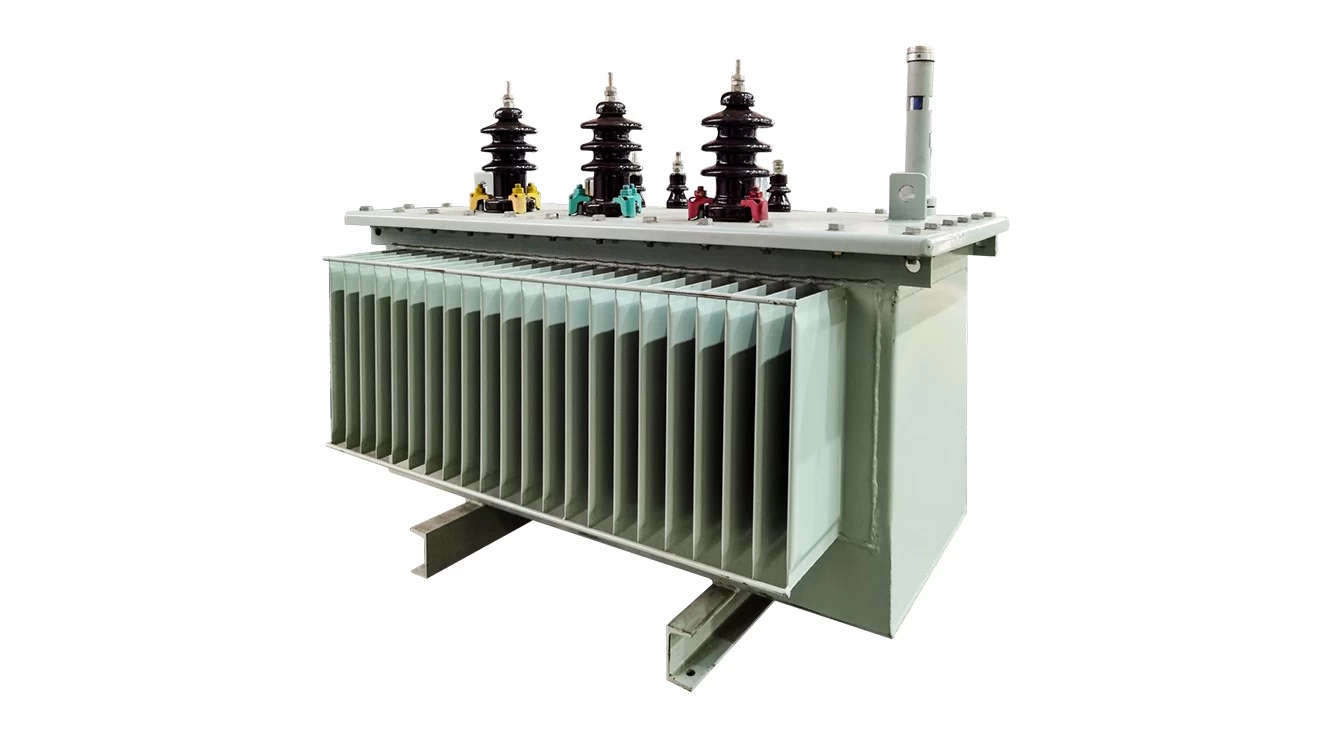

Oil-Immersed Distribution Transformer

- Normal use conditions of the product

- Ambient air temperature:+40℃- -45℃;

- Monthly average hot temperature:+30℃;

- Annual average hot temperature:+20℃;

- Altitude:≤1000m;

- Pollution level: class Ⅲ;

- Power supply voltage waveform: approximately sine wave.

►Overview

Oil-immersed power transformers are electrical appliances that use insulating oil as the insulating medium and are composed of cores, coils, voltage regulator switches, oil tanks, etc. to change voltage and transmit AC power. It has the characteristics of small size and strong weather resistance. Applicable to power systems, industrial and mining enterprises, transportation, post & telecommunications and scientific research bureaus, etc. It is divided into flat stacked core series, three-dimensional roll-core series, amorphous alloy series and other products below 35kV. The structure is flexible and diverse, the appearance is good-looking, and it can meet the needs of different users.

►Product Series

The structure is flexible and diverse, the appearance is good-looking, and it can meet the needs of different users.

| 10kV products | •S11(S13、S20、S22) series three-phase oil-immersed self-cooling double winding non-excitation voltage regulating distribution transformer •S13(S20、S22)-M.RLseries three-phase oil-immersed three-dimensional roll-core self-cooling double winding non-excitation voltage regulating distribution transformer •SH15(SH21、SH25) series three-phase oil-immersed self-cooling amorphous alloy core double winding non-excitation voltage regulating distribution transformer |

| 20kV products | •S11 series 20kV three-phase oil-immersed self-cooling double winding non-excitation voltage regulating distribution transformer •S13 series 20kV three-phase oil-immersed self-cooling double winding non-excitation voltage regulating distribution transformer |

| 35kV products | •S11 series 35kV three-phase oil-immersed self-cooling double winding non-excitation voltage regulating distribution transformer |

Note: If you need other types of single-phase and three-phase oil-immersed distribution transformers of 10-35kV, please contact our Transformer Manufacturer China team for specific technical parameters and requirements.

►Normal use conditions of the product

Ambient air temperature:+40℃- -45℃;

Monthly average hot temperature:+30℃;

Annual average hot temperature:+20℃;

Altitude:≤1000m;

Pollution level: class Ⅲ;

Power supply voltage waveform: approximately sine wave.

Note: If the use condition is more special than the above-mentioned conditions, please contact our transformer team for specific technical parameters and requirements.

►Product performance advantages (planar laminated core)

•There are no oil protection devices such as oil conservator and moisture absorber to ensure that the transformer oil does not come into contact with the air and ensure that the transformer oil can be used continuously for 20 years without any treatment.

•The seals are made of rubber with excellent performance, which can effectively prevent photoaging, electrical aging and thermal aging.

•Equipped with signal thermometer and pressure release valve, which enhances the reliability of operation.

•Using the vacuum oil injection process, external moisture and oxygen cannot enter the oil tank, thereby slowing down the aging rate of the insulating material and increasing the service life of the transformer.

•Changes in the volume of the transformer are compensated by the expansion and contraction elasticity of the corrugated tank wall.

•No hanging core inspection is required before the product is put into operation, and maintenance and upkeep are not required after it is put into operation, which greatly improves the reliability of the operation.

•It is wound with high-strength enameled wire (or paper-covered wire), has a cylindrical (or cake-type) structure, evenly distributed ampere-turns, reasonable insulation structure, and has high short-circuit resistance.

•The fasteners used in the fuel tank all use loose-proof nuts, which will not loosen even after long-distance transportation.

►Product performance advantages (three–dimensional roll-core)

Magnetic circuit optimization

•There are no seams between the layers of the three-dimensional winding core, the magnetic circuit is evenly distributed throughout, there is no obvious high-resistance area, and there is no distortion of the magnetic flux density at the seams.

•The direction of the magnetic flux is completely consistent with the orientation of the silicon steel sheet.

•The three-phase magnetic circuit lengths are equal, and the sum of the three-phase magnetic circuit lengths is the shortest.

•The three-phase magnetic circuit is symmetrical, and the three-phase no-load current is balanced.

►Low loss and significant power saving effect

•The magnetization direction of the three-dimensional roll-core is completely consistent with the rolling direction of the silicon steel sheet, and there are no overlaps between the core layers. The magnetic flux is evenly distributed throughout the magnetic circuit, with no obvious high-resistance areas and no magnetic flux density distortion on the joints. On the premise of the same material, compared with the laminated core, the iron loss process coefficient of the core is dropped from 1.3-1.5 to 1.05, this alone can reduce core loss by 10-20%.

•Due to the special three-dimensional structure, the amount of material used in the yoke part of the core is reduced by 25% compared with the traditional laminated core, and the reduced angular weight accounts for approximately 6% of the total weight of the core.

•The shearing treatment of the silicon steel sheet will deteriorate its magnetic permeability, and the three-dimensional roll-core will undergo high temperature (800℃) vacuum nitrogen-filled annealing treatment not only eliminates the mechanical stress of the core, but also refines the magnetic domain of the silicon steel sheet, improves the secondary recrystallization ability of the silicon steel sheet, and makes the performance of the silicon steel sheet much better than its original performance.

►Low noise

•The root causes of noise caused by the vibration of the transformer body are:

1) The magnetostriction of the silicon steel sheet causes the iron core to vibrate and generate noise;

2) There is electromagnetic attraction caused by magnetic flux leakage between the joints of the silicon steel sheets and the laminations, causing the core to vibrate and generate noise;

3) The operating magnetic density of the transformer is too high, approaching or reaching the saturation point, and the magnetic leakage is too large, generate noise.

•Since the three-dimensional roll-core is made by rolling silicon steel sheet strips continuously and tightly on a dedicated core winding machine, there are no seams and no noise caused by discontinuous magnetic circuits like the laminated core. At the same time, the three-phase magnetic circuit and magnetic flux are completely symmetrical, and the operating magnetic density is reasonably designed, so the product noise is greatly reduced.

►Structural Features

1.Core:The core is made of high magnetic permeability and low loss silicon steel sheets or amorphous alloy materials, and has a ladder-shaped multi-level joint structure, which is beneficial to reducing no-load loss and no-load current.

2.Winding:Class A or above insulating materials are used. The high-voltage coil adopts multi-layer cylindrical type, which has high production efficiency and good resistance to impulse voltage. The low-voltage coil mostly adopts foil type; the space utilization rate is good and the inter-layer capacitance is evenly distributed.

3.Clamp:I-shaped channel steel is used to tighten the core and stabilize the body to clamp and prevent loosening. The core is also grounded at a single point through the clamp.

4.Tank:The transformer oil tank body and insulating oil to isolate air and moisture. Corrugated sheet rectangular oil tanks are often used. The elasticity of the corrugated sheet can compensate for changes in the volume of the transformer oil caused by temperature rise and fall.